● Why gear lubrication & maintenance are important?

The reducer or gearbox, a key component in mechanical equipment, transmits the motion between the prime mover and the working machine;

Effective lubrication can reduce the wear of various friction pairs such as gear pairs, worm gear pairs and bearings in the gear box, and prolong the service life of the equipment;

Gear damage often comes from dry start, and effective lubrication can penetrate into the lattice so that the gear exposed to the gear oil will not damage the tooth surface during dry start;

Gears are large sources of energy consumption in factories. Effective lubrication and thus their low friction coefficient can greatly reduce the energy consumption and frictional heat of the gear box and lower the oil temperature.

Lubricants highly compatible with seals can slightly swell the seals, prolong seal life and reduce oil leakage.

● Why bearing lubrication & maintenance are important?

Authoritative data show that 36% of bearing failures are due to poor lubrication; most rolling bearings are lubricated with grease.

According to the working conditions, the appropriate lubricant grease can be used to reduce the wear of the bearing under high temperature, heavy load, high speed, water spray, dust and other environments, and prolong the service life.

● Why rope lubrication & maintenance are important?

The (steel wire) rope must not only bear the working pressure, but also ensure the safety of the production site; effective lubrication can meet the requirements of the rope load and safety at the same time;

If the (steel wire) rope is not sufficiently lubricated, it will cause damage, deformation, wire breakage, strand break of the rope core or even the whole rope breakage;

The penetrating lubricant can spread through and be absorbed in the hemp core and can be released to lubricate the steel wire rope when squeezed.

The steel wire rope with good lubricity can effectively reduce the wear between wires, between the strands, and the damage between the rope and the hook to prolong the service life;

Lubricant with strong adhesion, water & high temperature resistance can meet the requirements of the working conditions of the steel wire rope under high temperature and in the open air.

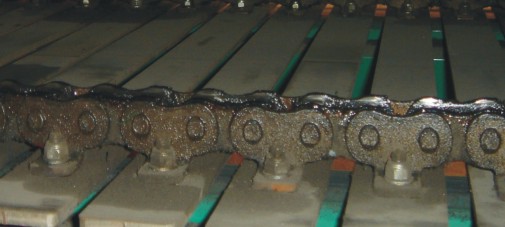

● Why chain lubrication and maintenance are important?

Improper maintenance will cause the chain to fail in the form of corrosion, rust, wear, elongation and even breakage;

Chain lubricant with strong penetrability and adhesion can effectively lubricate without dripping or polluting the working environment;

The wear of the chain is mainly between the sleeve and the pin, and the penetrating chain lubricant can penetrate into the sleeve and pin which are least lubricated so as to reduce wear;

The chain has a small surface area. A lubricant with strong adhesion can lubricate without polluting the ground;

A chain lubricant that is resistant to high temperatures, less volatile, and does not cause shrinkage and fish eyes can effectively meet the technological requirements of the coating line.

● Why bolt lubrication and maintenance are important?

As fasteners, bolts need to meet the tightening requirements to ensure the equipment stability and safety risk prevention and the maintenance needs of easy disassembly;

If the bolts are not lubricated, the installation is often not in place, leaving a hidden safety risk. Effective lubrication can help to apply sufficient force to ensure a proper installation;

During the working phase of the bolt, it is often affected by the environmental factors such as pressure, high temperature, water vapor, and corrosion, which causes rust, seizing, and difficulty in disassembly. Pre-applied assembly paste lubricant can effectively prevent seizing and facilitate maintenance and disassembly;

For bolts that are rusted and difficult to remove, the strong penetrating lubricant can penetrate between the threads and facilitate easy disassembly;

Before bolts are assembled, anti-seize agent is used to make installation easy and prevent high-temperature seizing. When disassembling, use disassembly-easing lubricant to make maintenance easier.